Deep Groundbed Impressed Current Cathodic Protection

for Underground Storage Tanks

All buried steel tanks have been provided with magnesium anodes. Attached to the outer wall of the tank, these anodes wear out in time, that is, they are consumed by corrosion. As the anodes corrode, they provide a very small current of electricity which protects the steel from corrosion. This is why magnesium anodes are also called "sacrificial anodes." This excellent protection system is called cathodic protection. The life of an anode is twenty to thirty years. At the end of the anode life, no more magnesium is available to protect the steel tank.

State laws require an annual cathodic protection test to verify the cathodic protection of the tanks. If the test fails, the tank owner has about 90 days to cathodically protect the tanks or else face significant monitory fines.

The owner has several options. His first option is to remove and replace the steel tanks with fiberglass reinforced plastic (FRP) tanks. This option is very costly.

His second option is to bury more magnesium anodes next to the tanks. Because magnesium has a low electrical potential with respect to steel, the anodes must be placed very close to the tanks, two to three feet away and even closer if the soil is dry. This can be accomplished by breaking up the concrete pad that covers the tanks, removing the pea stones in which the tanks are packed, placing new magnesium anodes next to the tanks, filling the hole with pea stone, and finally placing a new concrete pad over the tanks. Although less costly than the first option, this alternative is nevertheless pricy. The owner also loses operating time because the electrical support systems of the tanks are disturbed. Furthermore, placing magnesium anodes is risky because there is no way to adjust the electrical potential of the anode with respect to the buried steel of the tank. This often happens when the soil dries out.

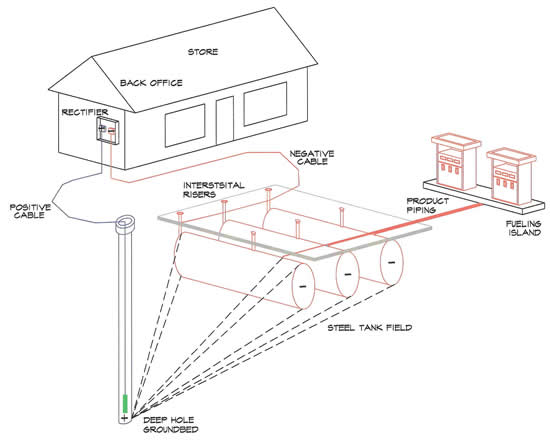

The third option, and the least costly, is to use non-sacrificial anodes and an impressed current system in place of magnesium. These anodes are buried deep in the soil some distance from the tanks. The potential of these anodes can be adjusted from two volts up to sixty. The power is supplied from a common household electrical outlet since impressed current requires less power than what a common light bulb would require, 115-120 volts alternating current (AC). With an impressed current system, the house current is converted into direct current (DC) for the anodes and moderated to the voltage necessary for cathodic protection by an electrical device called a rectifier.

The rectifier is a twelve inch long, six inch wide and four inch deep steel panel box containing an ammeter, a voltmeter and a time-logger. The ammeter discloses how much current flows to the anodes, the voltmeter shows the electrical potential of the anodes with respect to the tank, and the time logger reveals how many hours the rectifier has been active. The rectifier can be mounted anywhere where there is a house current power supply outlet, for example on an I-beam, a post anchored by the tanks, or inside an office.

The illustration above shows a deep groundbed impressed cathodic protection system. The system is a relatively low cost option because the tanks, pea stone, concrete pad, and all the wiring and pipes connecting the tanks to the fuel pumps, controllers and electrical power mains do not need to be disturbed. Only one deep hole must be drilled for the anodes. It is not necessary to place the anodes immediately next to the tanks; the hole can be five, ten or fifteen feet away from the tank pad and the current they provide can reach the tanks evenly distributed. As the illustration shows, multiple tanks can be cathodically protected simultaneously. Moreover, the potential can be dialed into the rectifier, something you cannot do with magnesium anodes. A shallow trench is all that is needed to bury the anode and tank cables.

Once a month, the tank owner is required by law to record the values shown by the rectifier meters. These values may vary slightly with the seasons. The time logger should show 8760 hours at the end of the first year, 17,520 at the end of year two, and so on. The cathodic protection system must be tested annually by a qualified individual.